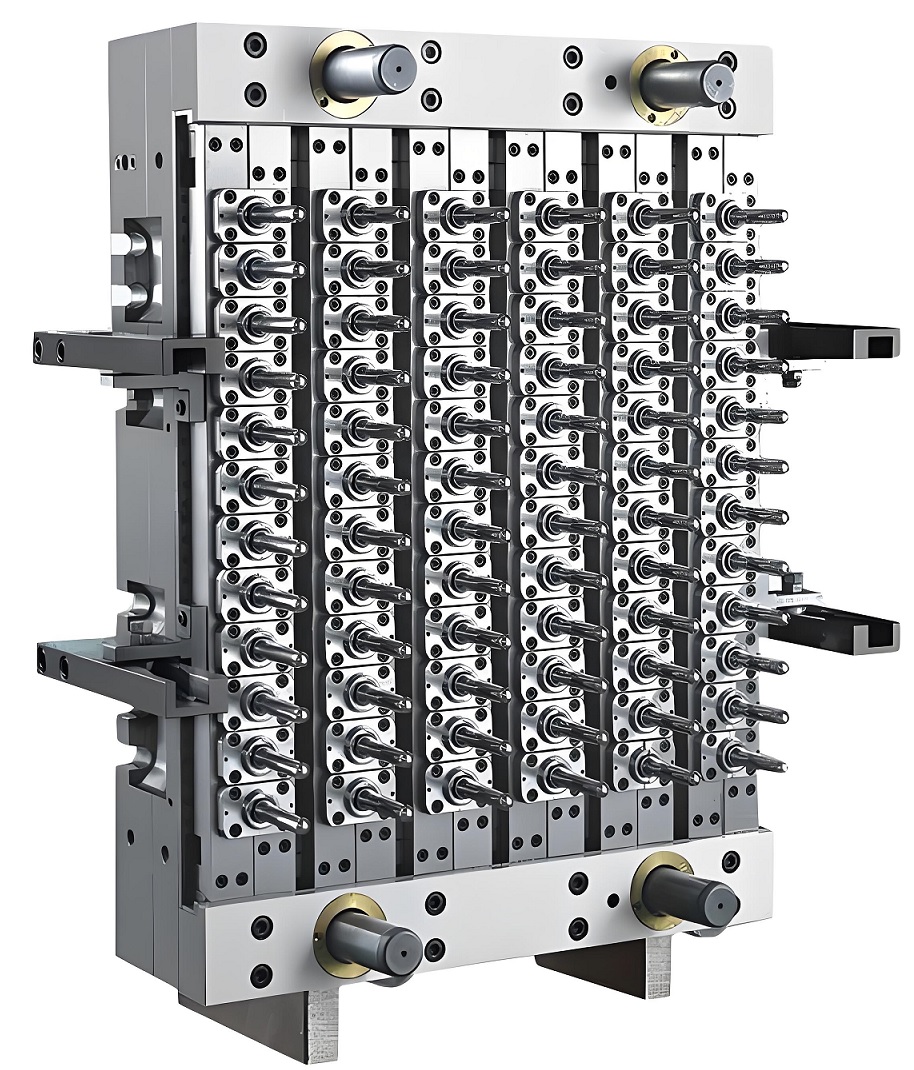

Hot runner molds

Hot runner mold, refers to a mold that uses a heating thermocouple device to keep the molten material in the channel from solidifying. Because it has a shorter moulding cycle than traditional molds and is more material efficient, hot runner molds are widely used in industrialized countries and regions around the world today.

Hot runner mold, refers to a mold that uses a heating thermocouple device to keep the molten material in the channel from solidifying. Because it has a shorter moulding cycle than traditional molds and is more material efficient, hot runner molds are widely used in industrialized countries and regions around the world today.

Hot runner system generally consists of several parts such as a hot nozzle, a splitter plate, a temperature control box, and accessories. Hot nozzles generally include two types: open hot nozzles and needle valve hot nozzles. Due to the fact that the form of the hot nozzle directly determines the selection of the hot runner system and the manufacturing of the mold, the hot runner system is often divided into an open hot runner system and a needle valve hot runner system accordingly. The splitter plate is used when the first mock examination has multiple cavities or multi-point feeding, single point feeding, but the material level is offset. The material is usually P20 or H13. Split plates are generally divided into two categories: standard and non-standard, and their structural form is mainly determined by the distribution of the mold cavity on the mold, the arrangement of nozzles, and the position of the sprue. The temperature control box includes the host, cables, connectors, and male and female sockets for wiring. Hot runner accessories typically include heaters and thermocouples, channel seals, connectors, and junction boxes.