The market is constantly changing, and consumers' demands for products are becoming more diverse and personalized. Once, a regular product could sell tens of thousands or even millions of sets, but now product updates are becoming faster and faster. It is very common for a set of molds that require huge investment to start trial production to have no orders afterwards. How should we respond to this changing situation? Perhaps quick and easy molds can significantly reduce your investment risk. Below is a brief description of the advantages and disadvantages of fast molds compared to traditional conventional molds.

Advantages of rapid prototyping:

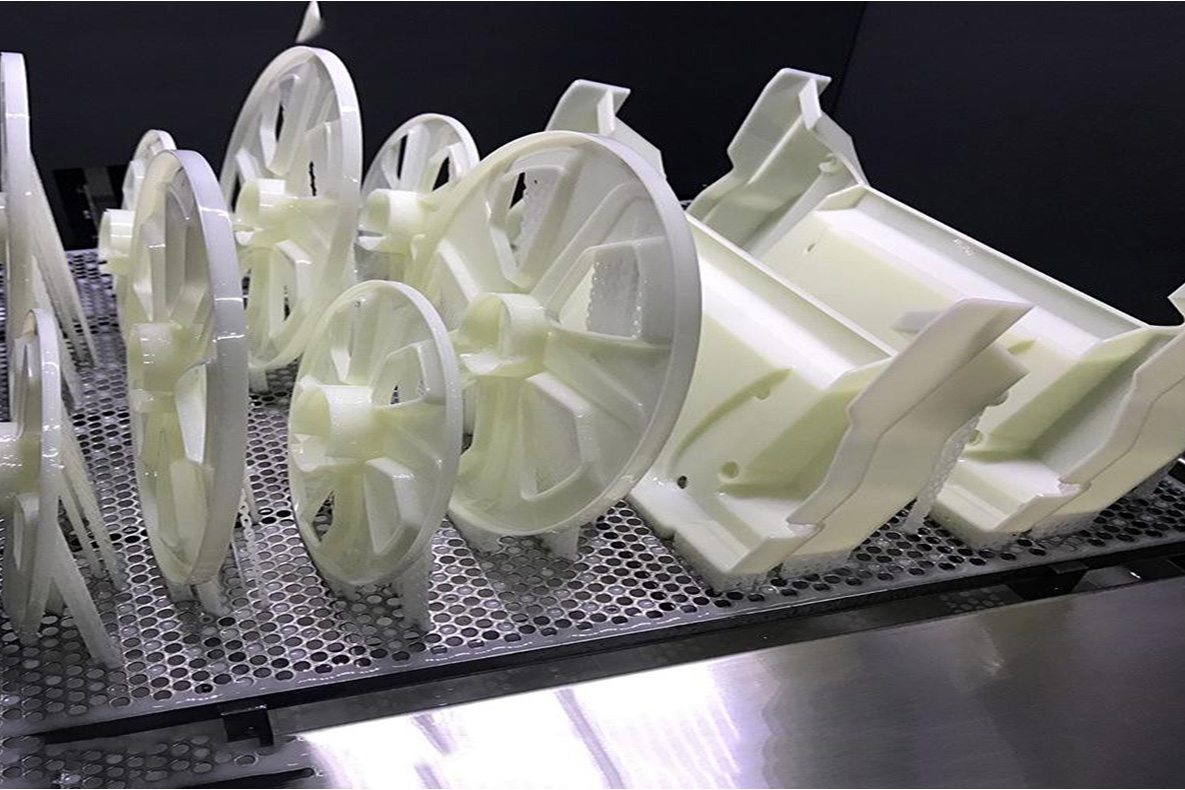

1. Fast speed, the same product can save 1/3 or even 1/2 of the development cycle compared to traditional conventional molds;

2. The price is low, and the same product can save more than 1/3 of the development cycle compared to traditional conventional molds, depending on the specific situation;

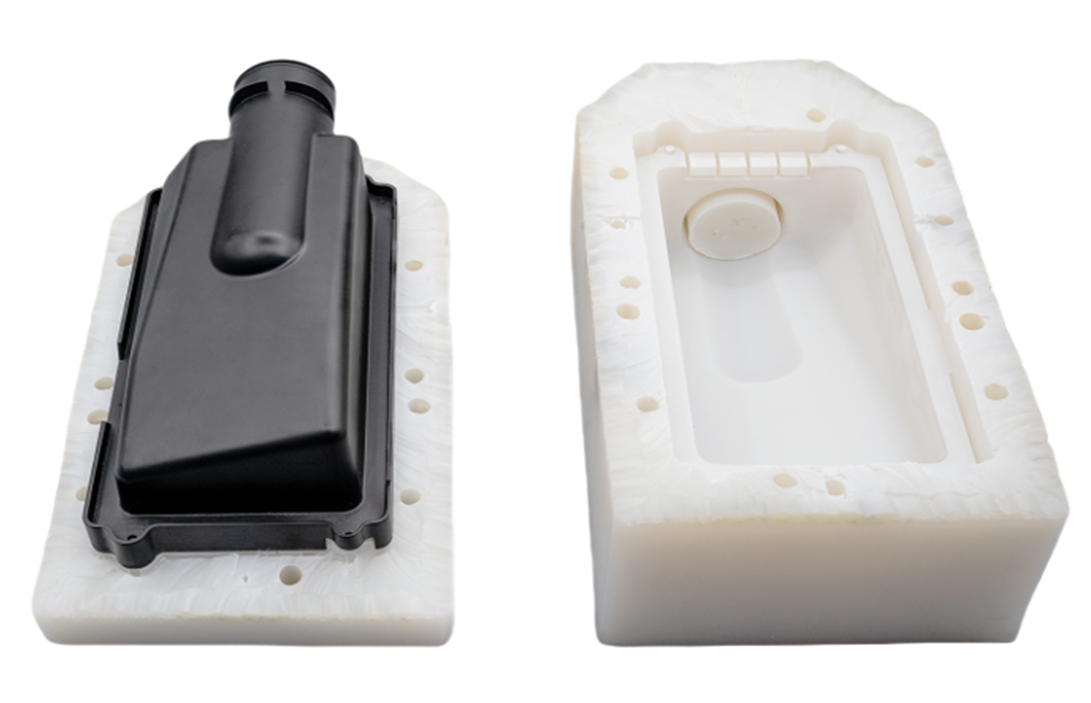

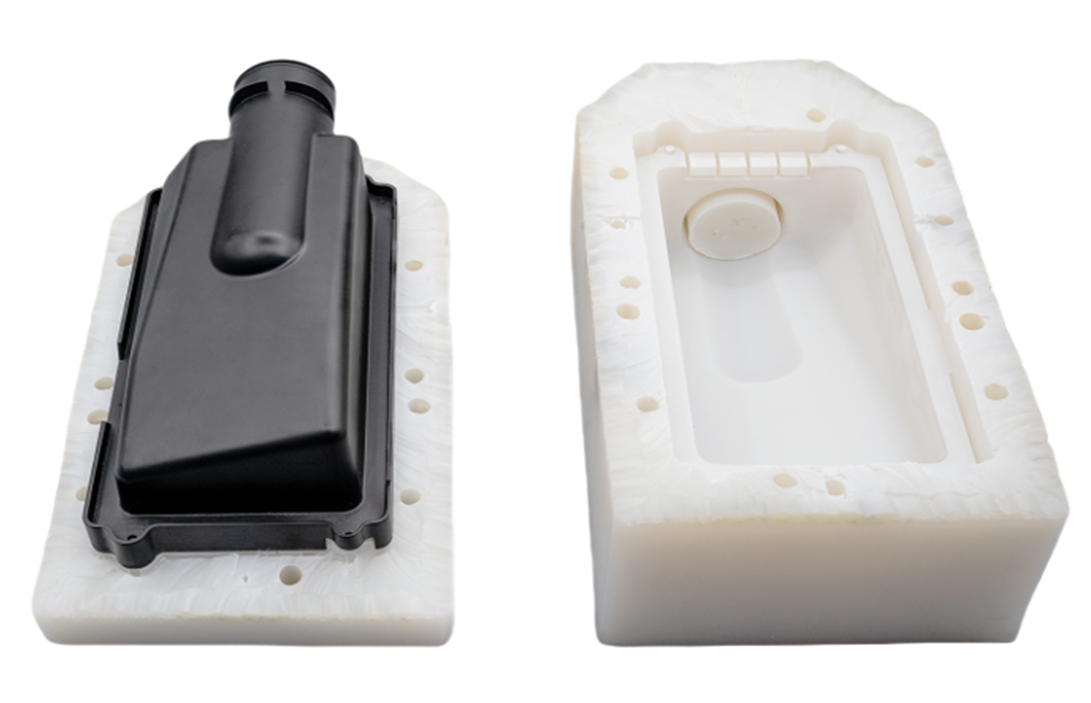

3. The product is aesthetically pleasing, and due to the same injection molding method as the official mold, the resulting product has almost no difference in effect from future mass production;

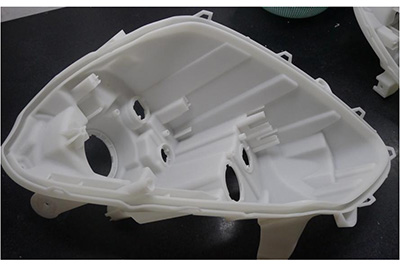

4. The materials are abundant, and various engineering plastic materials, even composite materials, can be selected, which is incomparable to CNC prototyping, 3D printing, and replication;

5. To reduce risks, many products always fantasize about becoming bestsellers at the beginning of development, but in reality, many molds are only made for one or two thousand sets and there are no orders left. If conventional formal molds are used to invest time and economic costs, this is well supplemented by rapid molds;

6. Flexible adaptability. In today's era where personalized and customized demands are becoming increasingly strong, many products only need to be made into a few hundred or even thousands of sets to meet market demand, which can also increase the added value of the product. Quick molds are also a good choice for this.