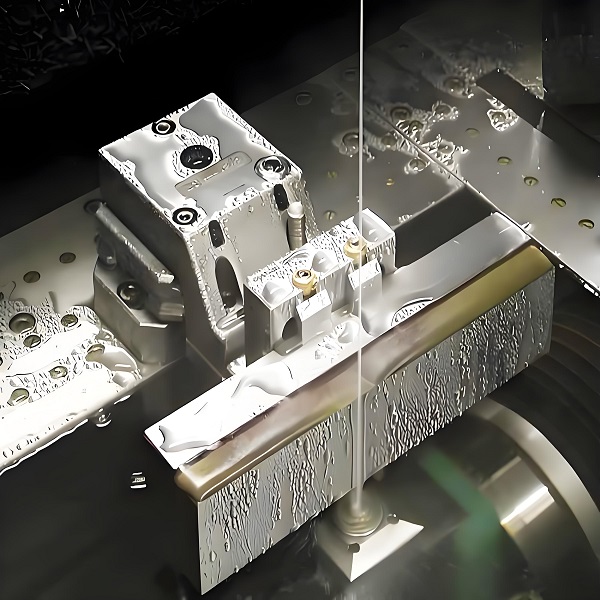

Wire-cut

Wire cutting processing is mainly applied in the manufacturing of injection molds in the following areas:

Wire cutting processing is mainly applied in the manufacturing of injection molds in the following areas:

Repair and maintenance: The mold may experience dimensional deviation or wear during use. Wire cutting can quickly correct the cavity size and shape, restore mold function, and reduce scrap rate.

Fast wire cutting processing: Fast wire cutting processing is a common method. In this processing method, the electrode wire moves back and forth at a high speed, usually around 810m/s. Its working principle is to use the pulse discharge phenomenon generated between the electrode wire and the workpiece to instantly generate high temperature, causing the workpiece material to be corroded.

Fast wire cutting processing: Fast wire cutting processing is a common method. In this processing method, the electrode wire moves back and forth at a high speed, usually around 810m/s. Its working principle is to use the pulse discharge phenomenon generated between the electrode wire and the workpiece to instantly generate high temperature, causing the workpiece material to be corroded.

In mold manufacturing, fast wire cutting is commonly used to process mold parts with relatively low precision requirements but certain production efficiency requirements. Simple stamping dies such as convex and concave molds. During the processing, the electric wire is driven by the wire storage cylinder to quickly travel back and forth between the guide wheels, continuously cutting the workpiece. Due to the rapid movement of the electrode wire, the wear and tear of the electrode wire is relatively uniform during the machining process, which is beneficial for ensuring a certain level of machining accuracy.

Fast wire cutting also has some limitations. Due to the high-speed reciprocating motion of the electrode wire, it is easy to cause shaking of the electrode wire, which affects the machining accuracy. Generally, the machining accuracy is around ± 0.01mm. Moreover, the surface roughness of the processed material is relatively high, usually with Ra between 2.5 5um.

Slow wire cutting processing: In mold manufacturing, slow wire cutting is mainly used for processing mold parts with high precision and high surface quality requirements. For example, key components such as the core and cavity of precision injection molds. Slow wire cutting can achieve extremely high machining accuracy, which can be controlled within ± 0.005mm, and the surface roughness Ra can reach 0.1 1um. This is because the electrode wire moves unidirectionally and is constantly updated, reducing the impact of electrode wire loss on machining accuracy and achieving better surface smoothness.