In modern manufacturing, mold manufacturing, as an important part of product production, requires extremely high processing accuracy and craftsmanship. With the development of technology, the application of high-precision CNC machining technology in the field of mold manufacturing is becoming increasingly widespread, bringing significant impacts and changes.

Mold manufacturing imposes strict requirements on the dimensional accuracy and surface quality of parts. Traditional processing methods have certain limitations in processing complex shapes and microstructures, making it difficult to meet the requirements of high-precision and complex geometric shapes. High precision CNC machining can achieve micrometer level machining accuracy through the high flexibility of the CNC system and advanced tool control, effectively improving the dimensional consistency and interchangeability of mold parts.

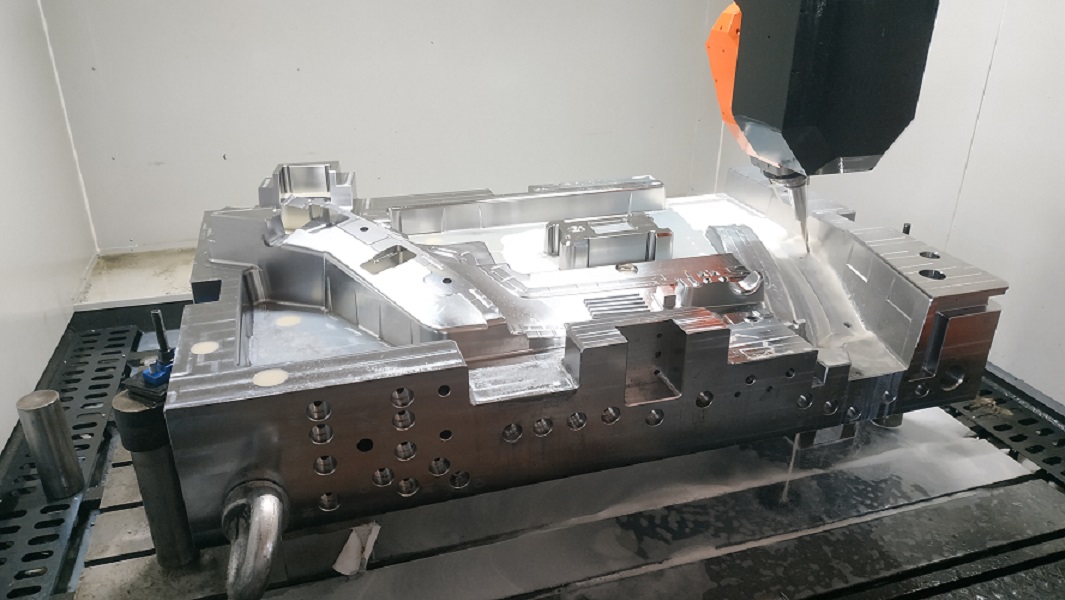

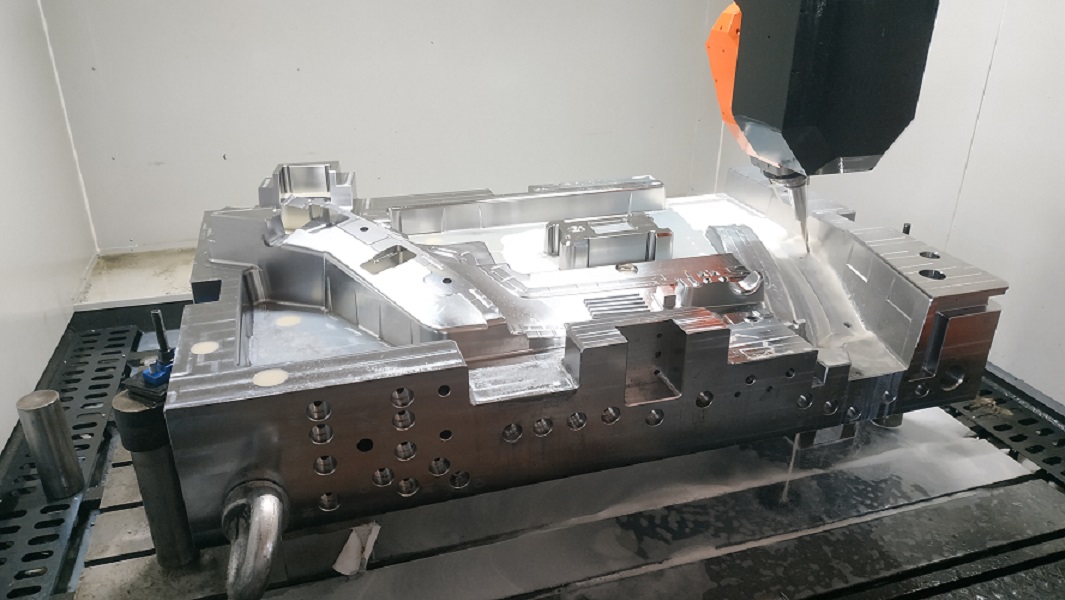

Taking automobile manufacturing molds as an example, automobile parts are diverse and structurally complex, and diversified molds ensure high precision to ensure the assembly quality and performance of the final product. High precision CNC machining can achieve efficient processing of complex surfaces through multi axis linkage machining, reducing traditional manual finishing processes and saving production time and labor costs. In actual production, mold manufacturers can improve processing efficiency and shorten mold delivery cycles by applying high-precision CNC technology while ensuring accuracy.

Mold manufacturing involves various materials, including high hardness alloy steel, mold steel, etc., which are difficult to process. High precision CNC machine tools are usually equipped with high-performance spindles and cutting systems, which can adapt to the machining needs of different materials, ensuring stability and machining quality. Especially in the micro machining of hard materials, CNC systems can achieve precise cutting parameter adjustment, reduce tool wear, extend tool life, and reduce machining costs.

In the field of electronic product mold manufacturing, there are stricter requirements for fine structures and high-precision surfaces. High precision CNC machining can achieve micrometer level shape control, effectively avoid mold surface defects, and improve product consistency and reliability. For example, the processing of mobile phone shell molds requires high smoothness and precise size matching. High precision CNC machining meets these requirements through high-frequency tool vibration control and delicate path planning.

In addition, the automation advantages brought by high-precision CNC machining technology have promoted the intelligent development of mold manufacturing. By combining with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, seamless integration from design to machining has been achieved. The direct transmission of design data to CNC machine tools reduces human intervention, lowers operational error rates, and improves production stability and repeatability. In mass production, this automated processing mode is particularly significant, which not only ensures the consistency of the mold, but also enhances the flexibility of production.

High precision CNC machining also plays an important role in the maintenance and repair of mold manufacturing. After long-term use, molds are inevitably prone to wear or deformation. By using high-precision CNC equipment for local repair and processing, the service life of the mold can be extended and the cost of remanufacturing can be reduced. Fine repair processing ensures the accuracy requirements after mold repair, meeting the needs of continuous production.

High precision CNC machining technology also provides support for design innovation in mold manufacturing. Under the limitations of traditional processing methods, complex internal cavities and intricate structures are difficult to process. The combination of high-precision CNC machining and multi axis machining technology enables designers to achieve more complex mold structure design, promoting the diversification and refinement of mold functions. For example, the cooling channel design inside the injection mold is more reasonable, which improves the heat dissipation efficiency of the mold and thus improves production efficiency.

High precision CNC machining technology also provides support for design innovation in mold manufacturing. Under the limitations of traditional processing methods, complex internal cavities and intricate structures are difficult to process. The combination of high-precision CNC machining and multi axis machining technology enables designers to achieve more complex mold structure design, promoting the diversification and refinement of mold functions. For example, the cooling channel design inside the injection mold is more reasonable, which improves the heat dissipation efficiency of the mold and thus improves production efficiency.

From an economic perspective, although the initial investment in high-precision CNC equipment is relatively high, mold manufacturing enterprises can achieve effective cost control in the medium to long term due to the improvement of processing efficiency and the reduction of scrap rates. High precision machining reduces rework and material waste, improves mold yield, and lowers overall manufacturing costs. In a fiercely competitive market environment, this technological advantage brings stronger competitiveness to enterprises.

In summary, the application of high-precision CNC machining technology in mold manufacturing has brought about improvements in dimensional accuracy and surface quality, enhanced the processing capability of complex structures, promoted the automation and intelligence of the manufacturing process, and supported mold design innovation and maintenance repair. Through these changes, the production efficiency and product quality of the mold manufacturing industry have been significantly improved. With the continuous development of technology, high-precision CNC machining will play a more important role in mold manufacturing, promoting the development of manufacturing processes to a higher level.

In modern manufacturing, mold manufacturing, as an important part of product production, requires extremely high processing accuracy and craftsmanship. With the development of technology, the application of high-precision CNC machining technology in the field of mold manufacturing is becoming increasingly widespread, bringing significant impacts and changes.

In modern manufacturing, mold manufacturing, as an important part of product production, requires extremely high processing accuracy and craftsmanship. With the development of technology, the application of high-precision CNC machining technology in the field of mold manufacturing is becoming increasingly widespread, bringing significant impacts and changes. Mold manufacturing involves various materials, including high hardness alloy steel, mold steel, etc., which are difficult to process. High precision CNC machine tools are usually equipped with high-performance spindles and cutting systems, which can adapt to the machining needs of different materials, ensuring stability and machining quality. Especially in the micro machining of hard materials, CNC systems can achieve precise cutting parameter adjustment, reduce tool wear, extend tool life, and reduce machining costs.

Mold manufacturing involves various materials, including high hardness alloy steel, mold steel, etc., which are difficult to process. High precision CNC machine tools are usually equipped with high-performance spindles and cutting systems, which can adapt to the machining needs of different materials, ensuring stability and machining quality. Especially in the micro machining of hard materials, CNC systems can achieve precise cutting parameter adjustment, reduce tool wear, extend tool life, and reduce machining costs. High precision CNC machining technology also provides support for design innovation in mold manufacturing. Under the limitations of traditional processing methods, complex internal cavities and intricate structures are difficult to process. The combination of high-precision CNC machining and multi axis machining technology enables designers to achieve more complex mold structure design, promoting the diversification and refinement of mold functions. For example, the cooling channel design inside the injection mold is more reasonable, which improves the heat dissipation efficiency of the mold and thus improves production efficiency.

High precision CNC machining technology also provides support for design innovation in mold manufacturing. Under the limitations of traditional processing methods, complex internal cavities and intricate structures are difficult to process. The combination of high-precision CNC machining and multi axis machining technology enables designers to achieve more complex mold structure design, promoting the diversification and refinement of mold functions. For example, the cooling channel design inside the injection mold is more reasonable, which improves the heat dissipation efficiency of the mold and thus improves production efficiency.

In summary, the application of high-precision CNC machining technology in mold manufacturing has brought about improvements in dimensional accuracy and surface quality, enhanced the processing capability of complex structures, promoted the automation and intelligence of the manufacturing process, and supported mold design innovation and maintenance repair. Through these changes, the production efficiency and product quality of the mold manufacturing industry have been significantly improved. With the continuous development of technology, high-precision CNC machining will play a more important role in mold manufacturing, promoting the development of manufacturing processes to a higher level.

In summary, the application of high-precision CNC machining technology in mold manufacturing has brought about improvements in dimensional accuracy and surface quality, enhanced the processing capability of complex structures, promoted the automation and intelligence of the manufacturing process, and supported mold design innovation and maintenance repair. Through these changes, the production efficiency and product quality of the mold manufacturing industry have been significantly improved. With the continuous development of technology, high-precision CNC machining will play a more important role in mold manufacturing, promoting the development of manufacturing processes to a higher level.