1. The mold clamping machine can accurately position and align various parts of the mold, ensuring that the position of each component of the mold is precise and error free during the clamping process, thereby ensuring the dimensional accuracy and quality stability of the molded product.

The mold is composed of multiple components, and the mold closing machine uses its precise positioning system to accurately connect these components during mold closing, avoiding dimensional deviations that may cause the molded product to not meet requirements and improving the consistency of product quality.

2. The mold clamping machine can provide stable and uniform clamping force, so that the pressure on various parts of the mold is balanced during the closing process, preventing deformation or damage of the mold due to uneven force, and extending the service life of the mold,

A stable and uniform clamping force can ensure that the mold fits tightly at all points during clamping, avoiding excessive local pressure that may cause mold wear or breakage, and reducing the cost of mold maintenance and replacement.

3. It can simulate the mold closing process in actual production, detect the fit of the mold in advance, timely discover defects in mold design or manufacturing, and facilitate correction and optimization before production.

By using a mold clamping machine to simulate mold clamping before formal production, problems such as unreasonable mold spacing and component interference can be discovered, avoiding the occurrence of defective products in large-scale production and reducing production costs.

4. The mold closing machine can quickly open and close the mold, improve production efficiency, reduce the time required for mold opening and closing, and increase the production frequency per unit time.

Quick opening and closing actions can make the production process more compact, shorten the production cycle of individual products, and thus improve overall production efficiency.

5. The mold closing machine has a high degree of automation control function, which can automatically complete a series of actions such as mold closing and locking according to preset parameters, reducing manual operation errors and labor intensity.

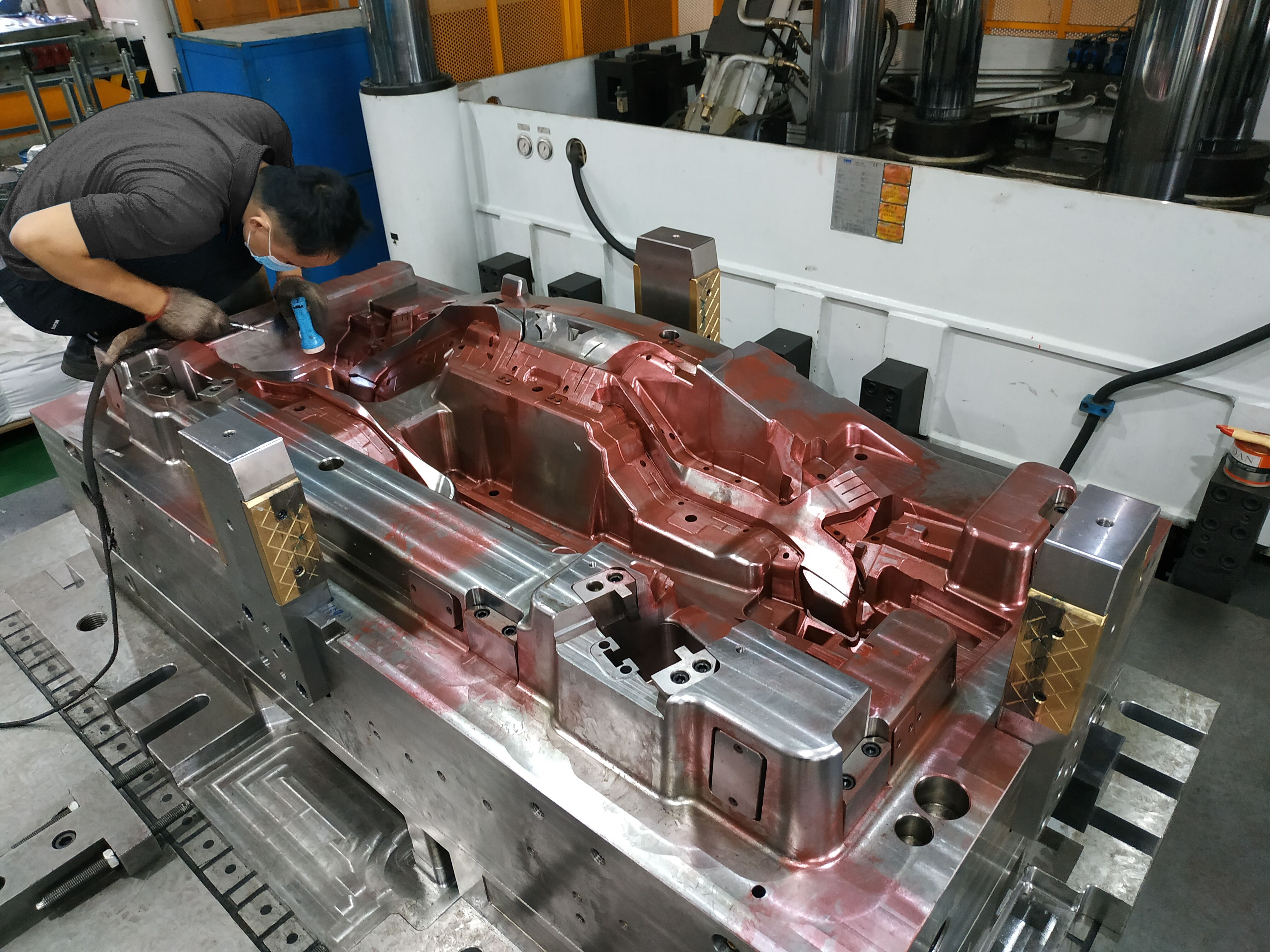

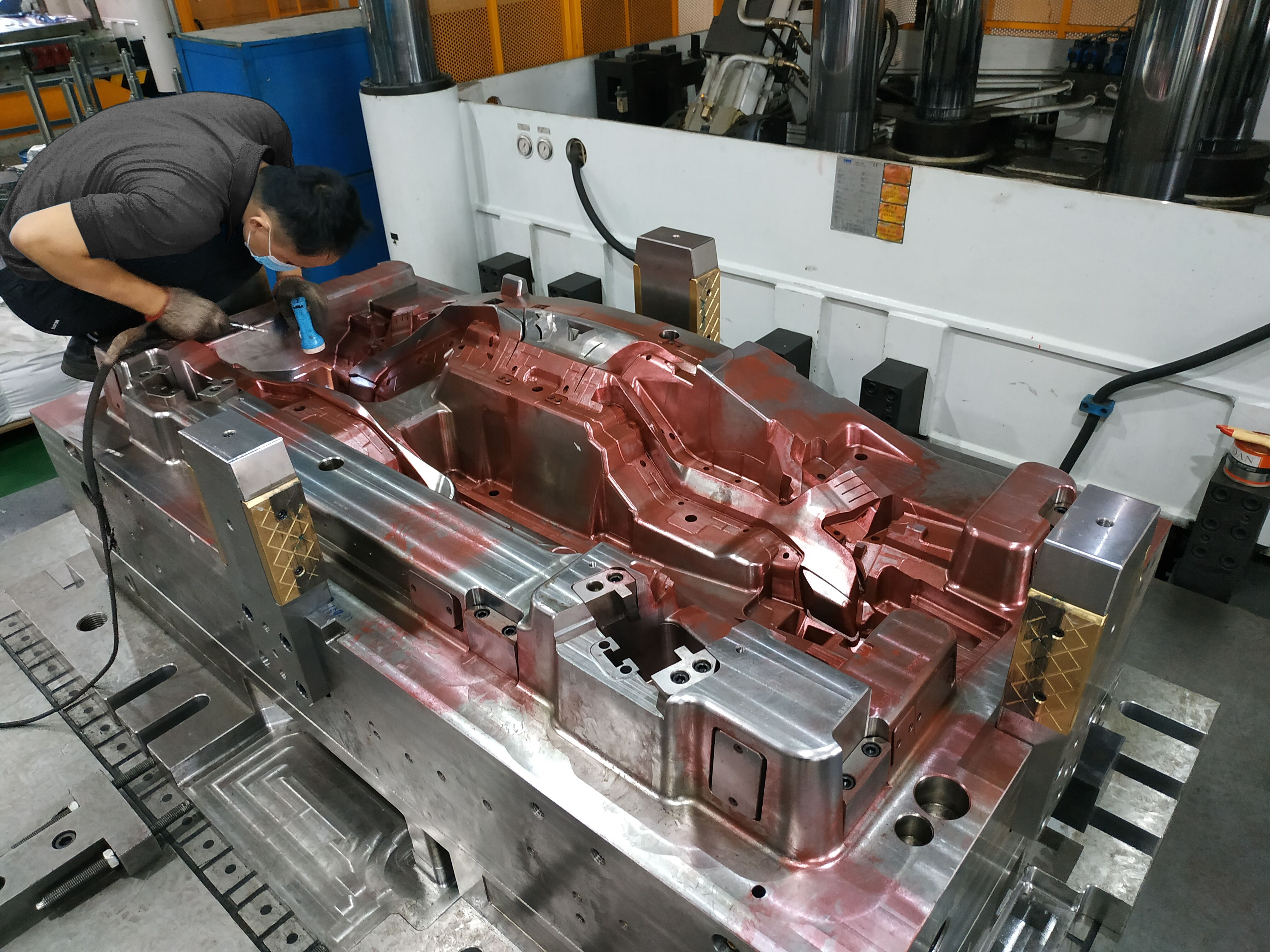

The mold clamping machine is a professional mold research and assembly testing equipment, mainly used for pressing and clamping the upper and lower molds with the required pressure during the later stage of mold production research and assembly.

The mold closing mechanism is a component that ensures the reliable closure and opening/closing action of the mold. The clamping mechanism must be able to provide sufficient clamping force to prevent product overflow.

1. The mold clamping machine can accurately position and align various parts of the mold, ensuring that the position of each component of the mold is precise and error free during the clamping process, thereby ensuring the dimensional accuracy and quality stability of the molded product.

1. The mold clamping machine can accurately position and align various parts of the mold, ensuring that the position of each component of the mold is precise and error free during the clamping process, thereby ensuring the dimensional accuracy and quality stability of the molded product. 4. The mold closing machine can quickly open and close the mold, improve production efficiency, reduce the time required for mold opening and closing, and increase the production frequency per unit time.

4. The mold closing machine can quickly open and close the mold, improve production efficiency, reduce the time required for mold opening and closing, and increase the production frequency per unit time.