Grinding

Grinding machines are mainly used for high-precision machining and surface treatment in mold manufacturing, with the following specific functions:

Grinding machines are mainly used for high-precision machining and surface treatment in mold manufacturing, with the following specific functions:

Common types of grinding machines:

Common types of grinding machines:

There are currently many popular grinding machines in the market, which can be divided into flat grinding machines, cylindrical grinding machines, internal cylindrical grinding machines, tool grinding machines, etc. according to the processing method. The following are several common types of grinding machines:

1. Surface grinder: Surface grinders are used to machine regularly shaped workpiece surfaces, typically for machining flat surfaces, chutes, convex grooves, serrations, and other workpieces.

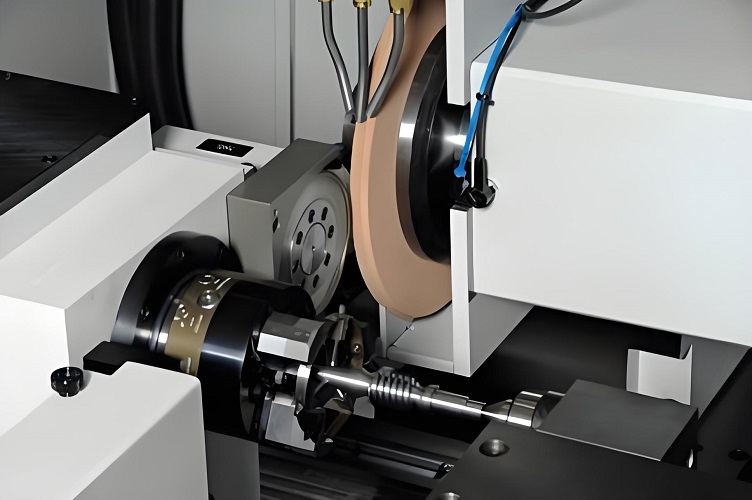

2. Cylindrical grinder: Cylindrical grinders are mainly used for processing cylindrical workpieces, including two types: external cylindrical grinders and internal cylindrical grinders.

3. Tool grinder: Tool grinders are used to machine various complex tools, such as cutting tools, milling cutters, drill bits, gears, etc.

In short, a grinder is a very important machine tool that can achieve high-precision machining and improve the quality and lifespan of parts. With the continuous development of technology, the application of grinding machines is also expanding. It is believed that in the near future, grinding machines will become one of the main forces in the machining industry.

The application of grinding machines in the process of mold manufacturing is very extensive. Different grinding machines have important applications at different stages of manufacturing. Generally speaking, grinding machines are mainly used in mold manufacturing for the following applications:

1. Rough grinding stage: The processing of molds is generally divided into two stages: rough machining and precision machining. In the rough machining stage, the initial formation of the mold needs to be carried out through a grinder, mainly to ensure that the basic shape of the mold is processed.

2. Precision grinding stage: In mold manufacturing, precision machining is a crucial step, with the application of grinding machines being the most prominent. Through the processing effect of the grinder, the surface of the mold can be treated very smoothly, improving the quality and service life of the mold.

3. Grinding stage: During the use of the mold, various reasons may cause damage to the surface of the mold, which requires grinding. Grinding machines are also very important in the grinding stage, completing grinding while ensuring the quality of the mold.

4、 Conclusion

In the process of mold manufacturing, grinding machine is one of the crucial equipment. By analyzing the application of grinding machines in mold manufacturing, we can understand their importance. Only by strengthening the understanding and application of grinding machines can we better ensure the quality of molds, improve their efficiency and lifespan.

In the vast system of modern industrial manufacturing, grinding machine processing is like a skilled "precision master", playing an irreplaceable key role. From key components in the aerospace industry to tiny precision components in electronic devices, the presence of grinding machines is ubiquitous, serving as the core guarantee for ensuring high precision and performance of products. In today's rapidly developing technology, the requirements for part accuracy in various industries have reached unprecedented heights. Grinding machines, with their excellent precision control capabilities, have become a key means of achieving high-precision part processing.

In the vast system of modern industrial manufacturing, grinding machine processing is like a skilled "precision master", playing an irreplaceable key role. From key components in the aerospace industry to tiny precision components in electronic devices, the presence of grinding machines is ubiquitous, serving as the core guarantee for ensuring high precision and performance of products. In today's rapidly developing technology, the requirements for part accuracy in various industries have reached unprecedented heights. Grinding machines, with their excellent precision control capabilities, have become a key means of achieving high-precision part processing.

Taking the aerospace field as an example, the machining accuracy of engine blades, as the core components of aircraft engines, directly affects the performance and reliability of the engine. In extreme working environments of high temperature, high pressure, and high-speed rotation, blades must have extremely high dimensional accuracy and surface quality to ensure efficient and stable operation of the engine. Grinding machine processing can control the dimensional tolerance of blades within a very small range, and the surface roughness can reach the micrometer or even nanometer level, meeting the strict requirements for high-precision components in the aerospace industry.

Looking at the medical device industry again, many precision components such as electrodes for pacemakers and key transmission structures for surgical instruments require extremely high machining precision. These components come into direct contact with the human body, and any slight deviation in accuracy may affect the normal use of medical equipment and even endanger the patient's life safety. Grinding machines, with their high-precision grinding capabilities, can provide the medical device industry with precision components that meet strict standards, ensuring the safety and effectiveness of medical devices.

In the field of material processing, there are always some "hard bones" that deter ordinary processing methods, but grinder processing can easily handle them and become a "sharp tool" for processing hard materials. Materials with high hardness such as quenched steel and hard alloys are widely used in industrial production. They have become ideal materials for manufacturing key components due to their excellent wear resistance, high strength, and high temperature resistance.

In industrial manufacturing, many workpieces have complex and diverse shapes, and conventional processing methods often fail to meet their accuracy and surface quality requirements. In this case, grinding machine processing, with its unique advantages, has become the key to solving the problem of complex shape processing.

Mold manufacturing is a field that requires extremely high demands for processing complex shapes. Taking the cavity of an injection mold as an example, its internal structure often contains various complex features such as irregular surfaces, inverted buckles, and thin walls, which play a decisive role in the molding quality of plastic products. Traditional cutting methods are greatly limited in terms of tool accessibility and cutting angle when facing these complex shapes, which can easily lead to machining blind spots and accuracy deviations. Grinding machine processing can be achieved through CNC forming grinding technology, which precisely controls the motion trajectory of the grinding wheel based on the three-dimensional model of the mold cavity, achieving high-precision grinding of irregular cavities. During the grinding process, the grinding wheel can grind along complex curves and surfaces to ensure that all parts of the mold cavity meet the design requirements for accuracy and surface roughness, providing a strong guarantee for the high-quality production of plastic products.