In the manufacturing process of plastic products, molds are the soul. Many enterprises often encounter the following problems in production:

Is there shrinkage or wire drawing on the surface of injection molded products? Is it difficult to control size deviation? Long production cycle and low mold changing efficiency?

The root of these problems often lies in mold design and manufacturing. A good mold not only determines product quality, but also greatly affects production efficiency and manufacturing costs.

So, how do plastic molds affect product quality and production efficiency?

1、 Die precision=guarantee line of product quality

a. The mold determines the dimensional tolerance of the product

The dimensional accuracy of plastic parts is not determined by the injection molding machine, but by the precision of the mold.

Poor dimensional accuracy of mold kernels can lead to products being larger or smaller;

Misalignment of inserts can cause deformation, eccentricity, and uneven thickness;

Poor balance in the mold cavity and dimensional errors in the molded product, affecting assembly.

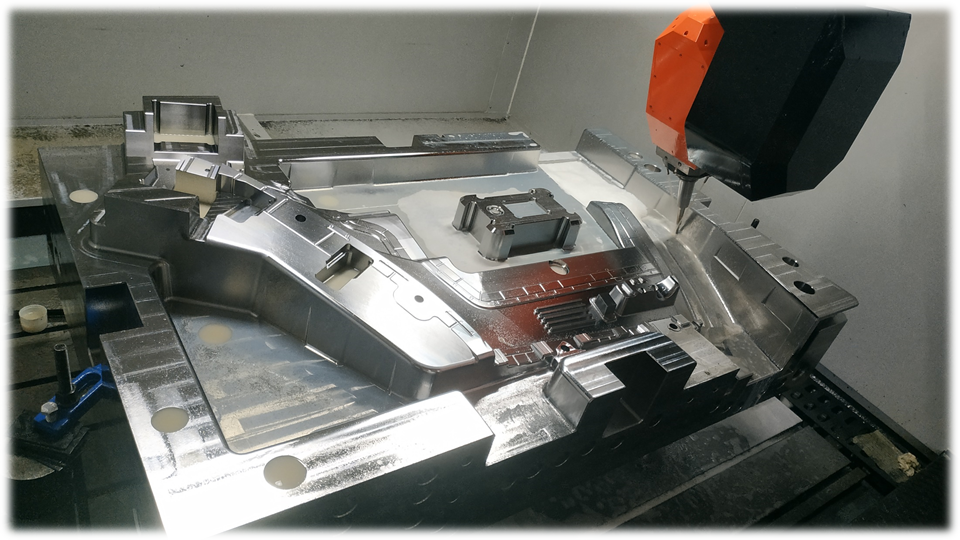

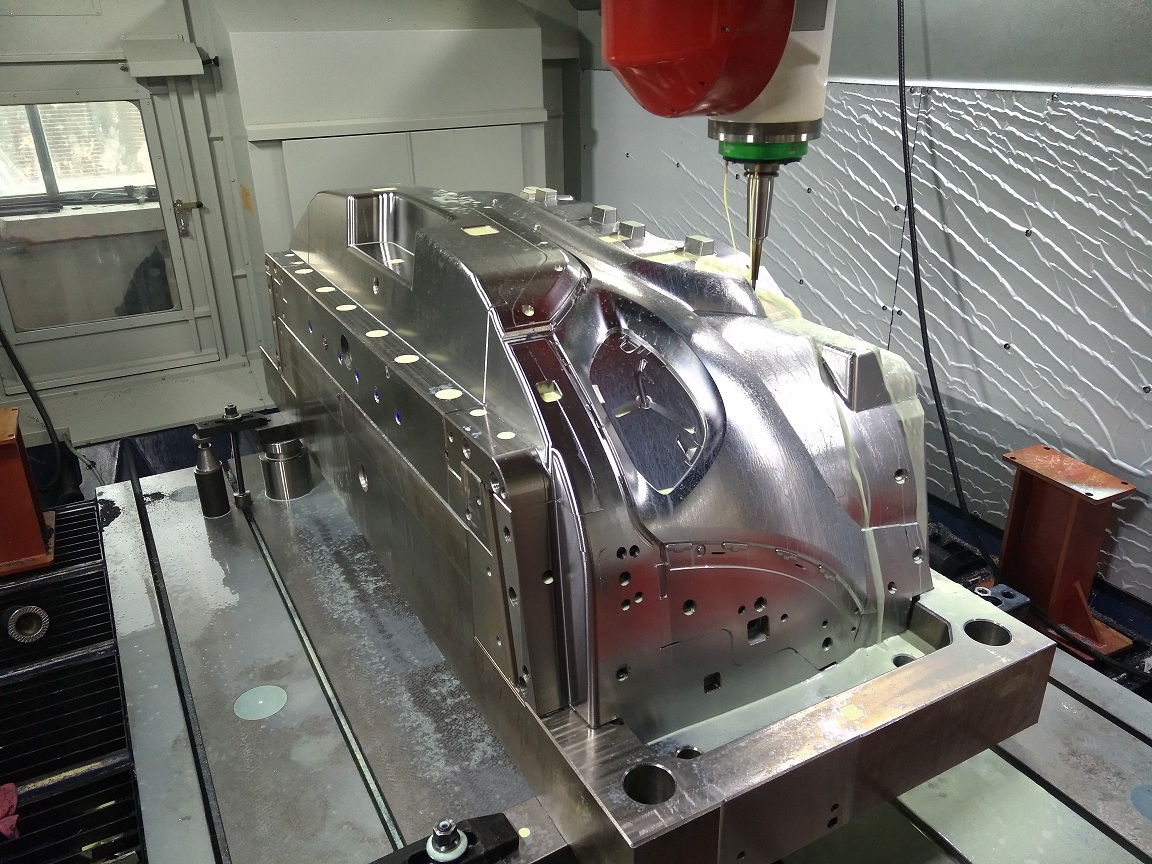

High precision molds are usually processed using equipment such as five axis machining centers and mirror spark machines, combined with three-dimensional inspection of the mold core to ensure that product dimensions are controlled within ± 0.02mm.

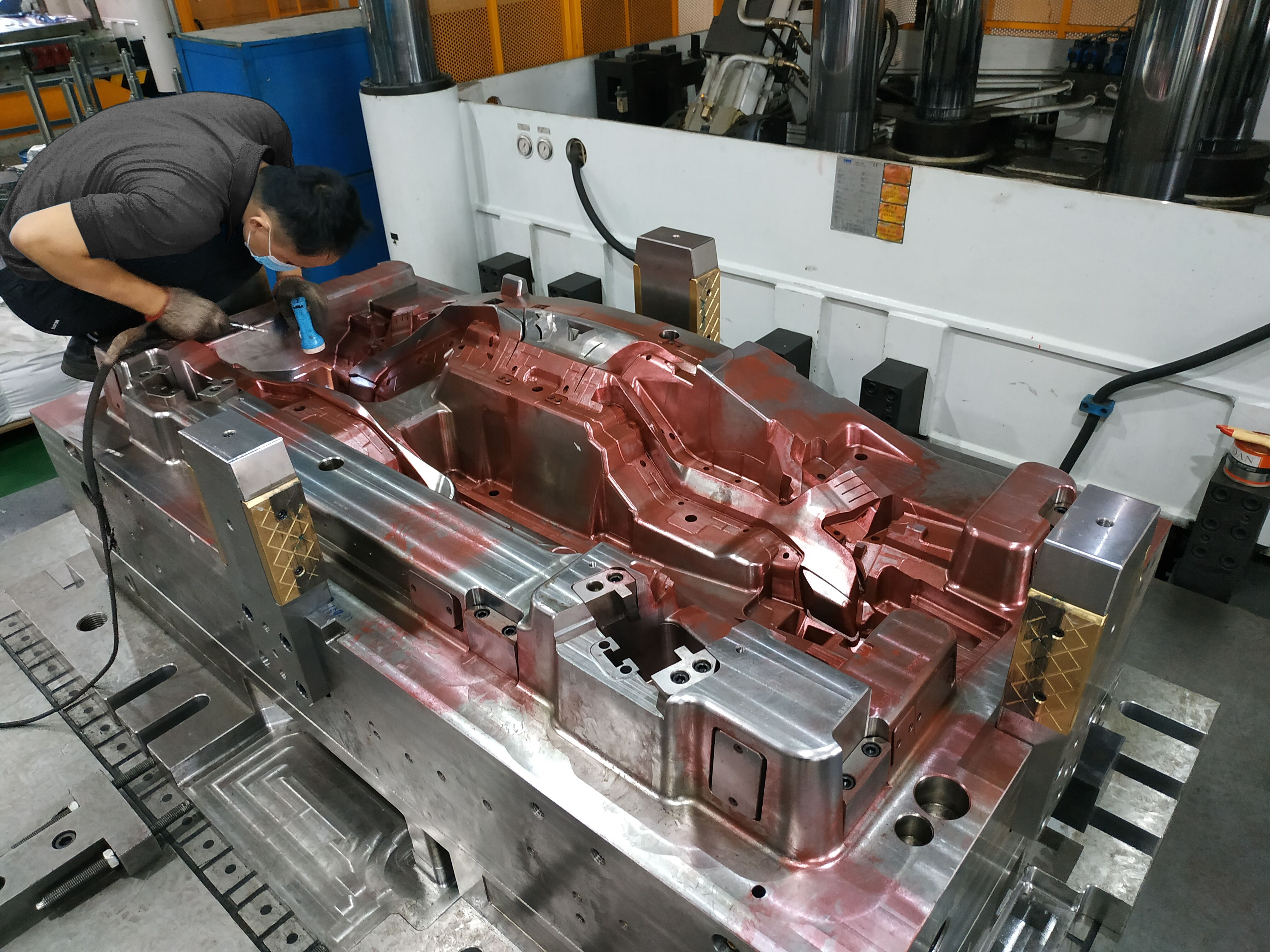

b. Mold structure affects product appearance and performance

Good mold structure design will directly improve the surface and strength performance of plastic parts:

The design of the flow channel system determines whether the plastic filling is full and whether it is clamped and brushed; Exhaust design affects whether the product has burn marks, air streaks, and black spots; The cooling water circuit is related to whether it shrinks, bends or deforms; The demolding structure determines whether the product surface is scratched, affecting its appearance

If customers have high requirements for the surface of the product (such as mirror finish, no defects), mirror polishing, chrome plating, nitriding and other treatments of the mold are particularly important.

2、 Mould manufacturing process determines production efficiency

a. The mold cooling system directly affects the molding cycle

Whether the cooling system layout of the mold is reasonable is one of the most direct factors affecting injection molding efficiency.

Optimizing waterways can reduce cooling time by 30%; Multi zone circulating cooling can prevent product shrinkage and deformation; The mold temperature control system can meet the requirements of high gloss seamless injection molding. A high-quality mold can reduce the original 30 second molding cycle to 20 seconds, producing millions of products annually.

b. Mold structure affects the degree of automation

With the widespread introduction of robotic arms and automatic mold demolding systems in the injection molding industry, the mold structure also needs to meet the requirements of intelligent manufacturing.

The three board mold structure is more suitable for mechanical arm parts retrieval; Automatic ejection system reduces manual intervention; Hot runner molds can reduce nozzle processing time. Our company is equipped with a robotic injection molding production line, and all molds are pre-set with automation solutions. Changing molds only takes 3 minutes, greatly improving efficiency.

c. Mold lifespan affects maintenance costs and downtime

The lifespan of the mold determines the frequency of mold replacement and equipment downtime.

Ordinary mold lifespan: 100000 mold cycles, prone to wear and tear; High end mold lifespan: 500000 to 1 million mold cycles, long-lasting stability. Molds with short service life not only increase the frequency of mold replacement, but also lead to frequent mold maintenance, production interruption, and production capacity loss.

3、 What key factors determine the quality of the mold?

a. Design phase (DFM analysis)

Everything starts from the source. Good mold design must undergo DFM (Design for Manufacturability) analysis:

Is the thickness of the product uniform? Is there a demolding slope? Is there a potential area of gas entrapment or shrinkage? Our company submits DFM reports and optimization suggestions before mold development to ensure risk avoidance from the design stage.

b. Processing accuracy (equipment and experience)

High quality molds cannot be separated from high-precision processing equipment and an experienced team of engineers:

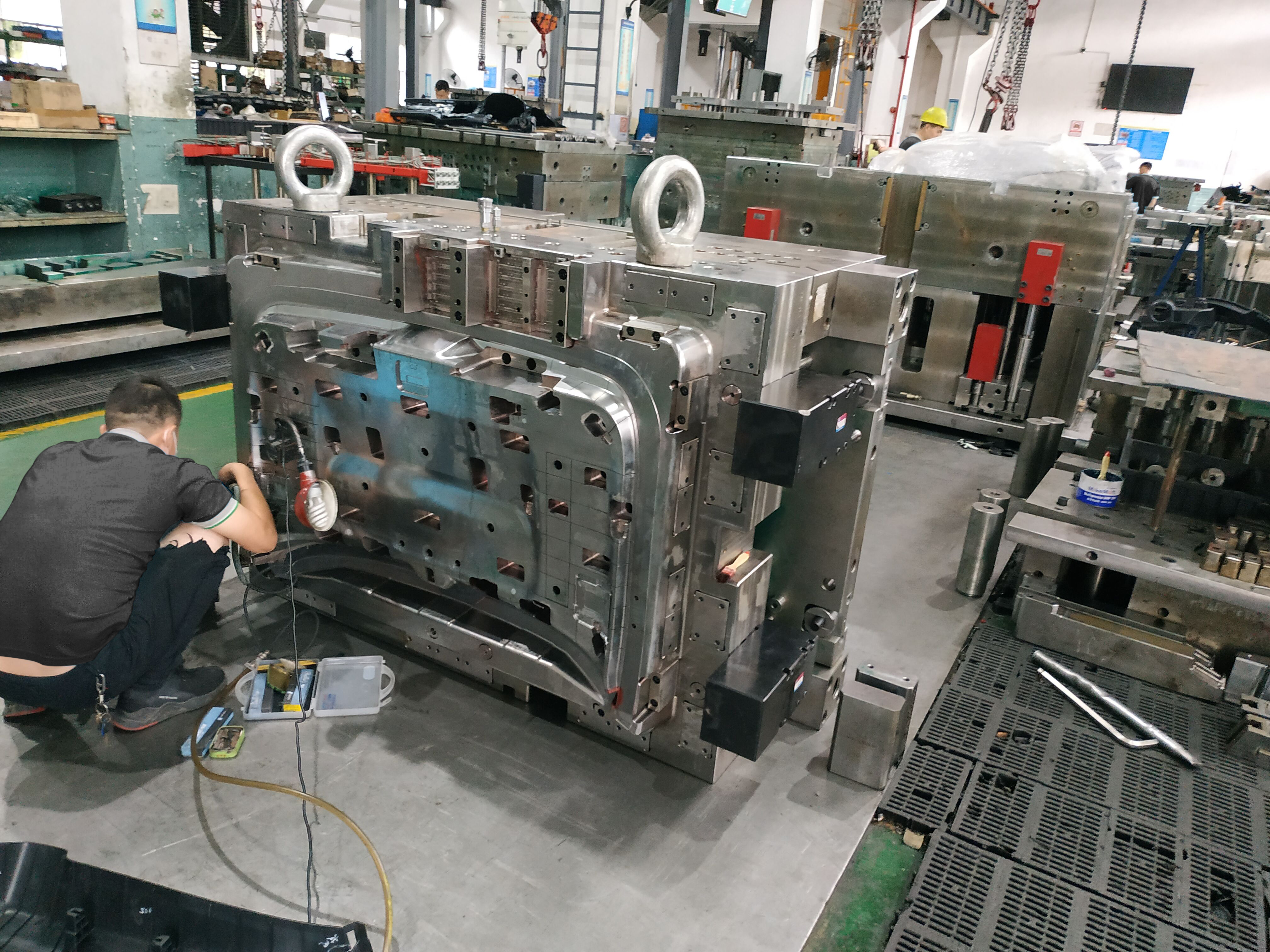

CNC machining accuracy ≤± 0.005mm; mirror surface spark machine creates high gloss molds; Three dimensional full inspection ensures that each mold core meets the required size standards; Full mold debugging, sealing testing, and thermal balance testing after mold assembly. All molds must undergo triple verification of "trial mold+sample confirmation+size report" before leaving the factory.

c. Post cooperation and maintenance support

A point that many customers overlook: the production of molds is not the end point, but the beginning of long-term use.

A responsible mold supplier must provide the following support services:

Mold repair and maintenance; Replacement of mold spare parts (such as ejector pins and sliders); Suggestions for injection molding parameters and assistance in analyzing molding issues; Unified archiving and management of multi project mold data.

4、 Make the product more stable and efficient

As a manufacturer specializing in high-precision plastic mold design and injection molding, Dongguan Yisen Precision Mold Co., Ltd. has delivered thousands of sets of molds to global customers, widely used in:

Electronic and electrical casing molds; Intelligent gas valve shell mold; Microscope structural component mold; Medical parts injection molds, etc.

We deeply understand that good molds make good products; Efficient molds are the key to high production in factories.

Our advantages include:

a. Free Product Structure Optimization and DFM Report

b. One stop service for molds and injection molding

c. All molds undergo CMM inspections and sample confirmation

d. Injection molding automation+mechanical arm combined with mold structure design

e. Mold delivery time as short as 18 days, efficient service without missing project milestones

high-quality plastic mold is not just a disposable tool, it is the source guarantee of your product competitiveness, manufacturing efficiency, and brand reputation.