EDM

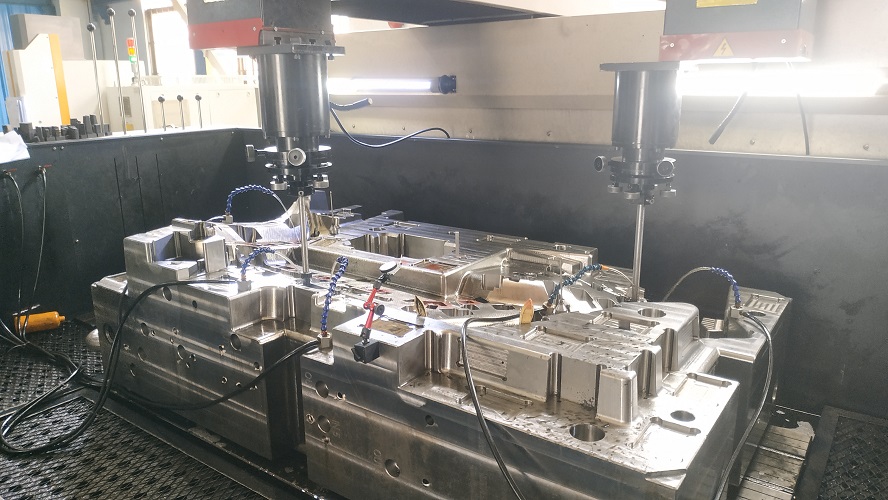

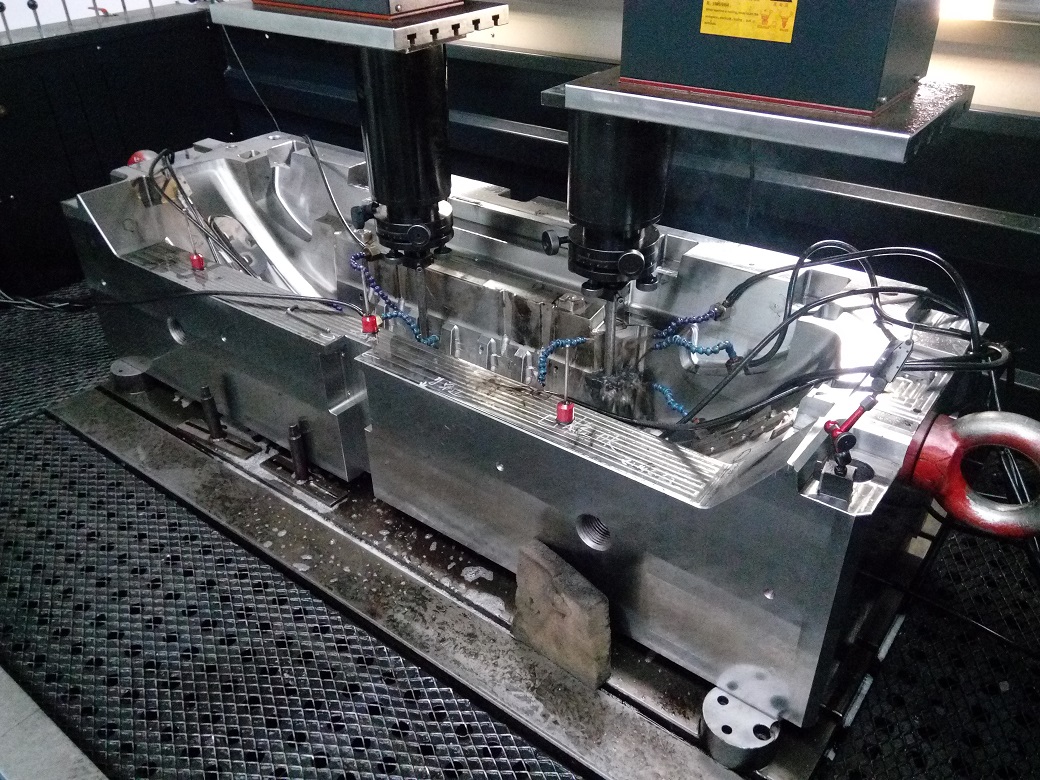

Electric discharge machining, abbreviated as EDM, is a key technology in the fields of mold manufacturing and mechanical processing. The basic principle is to use the pulse discharge phenomenon between the tool electrode and the workpiece, and achieve the erosion of the workpiece through the high temperature effect of the electric spark. During the machining process, the tool electrode and the workpiece are connected to different poles of the pulse power supply, and both are immersed in insulating dielectric fluid. As the tool electrode gradually approaches the workpiece, when the distance between the two is reduced to a certain extent, the dielectric fluid is broken down, forming a plasma channel. The high-temperature plasma in this channel bombards the surface of the workpiece, and the instantaneous temperature can reach up to 10000 ℃. Under this high temperature, the surface material of the workpiece evaporates, melts, and implodes, forming tiny molten pools. Subsequently, the discharge stops and enters the pulse interval period. Afterwards, a new cycle begins and spark discharge continues. This cyclic process can be repeated thousands of times per second, while the dielectric fluid continuously flushes and removes the eroded material. In the end, most of these materials were washed away, while a small portion remained on the surface of the workpiece, forming a unique morphology with features such as particle spheres, craters, and microcracks. It is worth noting that during the discharge process, phenomena such as plasma formation, interaction between electrons and ions, heat transfer, and material repulsion all exhibit a certain degree of randomness. In order to produce a specific three-dimensional shape, the electrode will move flexibly in three-dimensional space, thereby carving the required three-dimensional contour on the workpiece

Electric discharge machining, abbreviated as EDM, is a key technology in the fields of mold manufacturing and mechanical processing. The basic principle is to use the pulse discharge phenomenon between the tool electrode and the workpiece, and achieve the erosion of the workpiece through the high temperature effect of the electric spark. During the machining process, the tool electrode and the workpiece are connected to different poles of the pulse power supply, and both are immersed in insulating dielectric fluid. As the tool electrode gradually approaches the workpiece, when the distance between the two is reduced to a certain extent, the dielectric fluid is broken down, forming a plasma channel. The high-temperature plasma in this channel bombards the surface of the workpiece, and the instantaneous temperature can reach up to 10000 ℃. Under this high temperature, the surface material of the workpiece evaporates, melts, and implodes, forming tiny molten pools. Subsequently, the discharge stops and enters the pulse interval period. Afterwards, a new cycle begins and spark discharge continues. This cyclic process can be repeated thousands of times per second, while the dielectric fluid continuously flushes and removes the eroded material. In the end, most of these materials were washed away, while a small portion remained on the surface of the workpiece, forming a unique morphology with features such as particle spheres, craters, and microcracks. It is worth noting that during the discharge process, phenomena such as plasma formation, interaction between electrons and ions, heat transfer, and material repulsion all exhibit a certain degree of randomness. In order to produce a specific three-dimensional shape, the electrode will move flexibly in three-dimensional space, thereby carving the required three-dimensional contour on the workpiece

.

EDM, Electrical discharge machining, as an efficient manufacturing technology, is applicable to all conductive materials regardless of their mechanical properties. It utilizes non-contact thermal processes and is widely used in various fields such as aerospace, automotive, tools, molds, and surgical instruments, especially in processing difficult to machine materials with complex geometric shapes. In the mold manufacturing and tool industry, EDM technology is particularly widely used and has become a common method for manufacturing prototypes and producing parts. With the continuous development of the mold industry, the shapes of molds are becoming increasingly complex, the requirements for dimensional accuracy are becoming more stringent, and the difficulty of processing is constantly increasing. However, electric discharge technology can overcome the high strength and hardness of mold steel, easily process any shape, while maintaining high precision, perfectly meeting the needs of mold production.

Electric discharge machining technology plays a crucial role in mold manufacturing, covering the processing of large molds, precision molds, complex cavities, and high-strength and high hardness mold materials. Its unique advantages include the ability to process high-strength and hard tool and mold materials, as well as special parts and complex shapes in the mold cavity; Due to the lack of direct contact between the tool electrode and the workpiece, tool wear and mechanical stress issues have been reduced; Its special processing method and control system make automated production and control more outstanding; Meanwhile, the workpiece and tool electrodes have minimal deformation, ensuring high precision in machining dimensions.

Electric discharge machining technology plays a crucial role in mold manufacturing, covering the processing of large molds, precision molds, complex cavities, and high-strength and high hardness mold materials. Its unique advantages include the ability to process high-strength and hard tool and mold materials, as well as special parts and complex shapes in the mold cavity; Due to the lack of direct contact between the tool electrode and the workpiece, tool wear and mechanical stress issues have been reduced; Its special processing method and control system make automated production and control more outstanding; Meanwhile, the workpiece and tool electrodes have minimal deformation, ensuring high precision in machining dimensions.