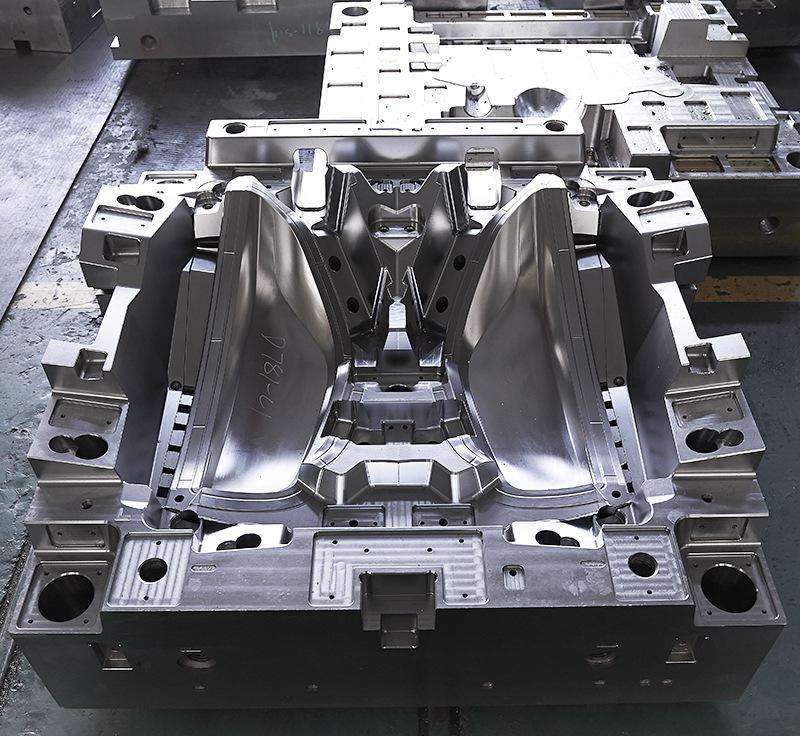

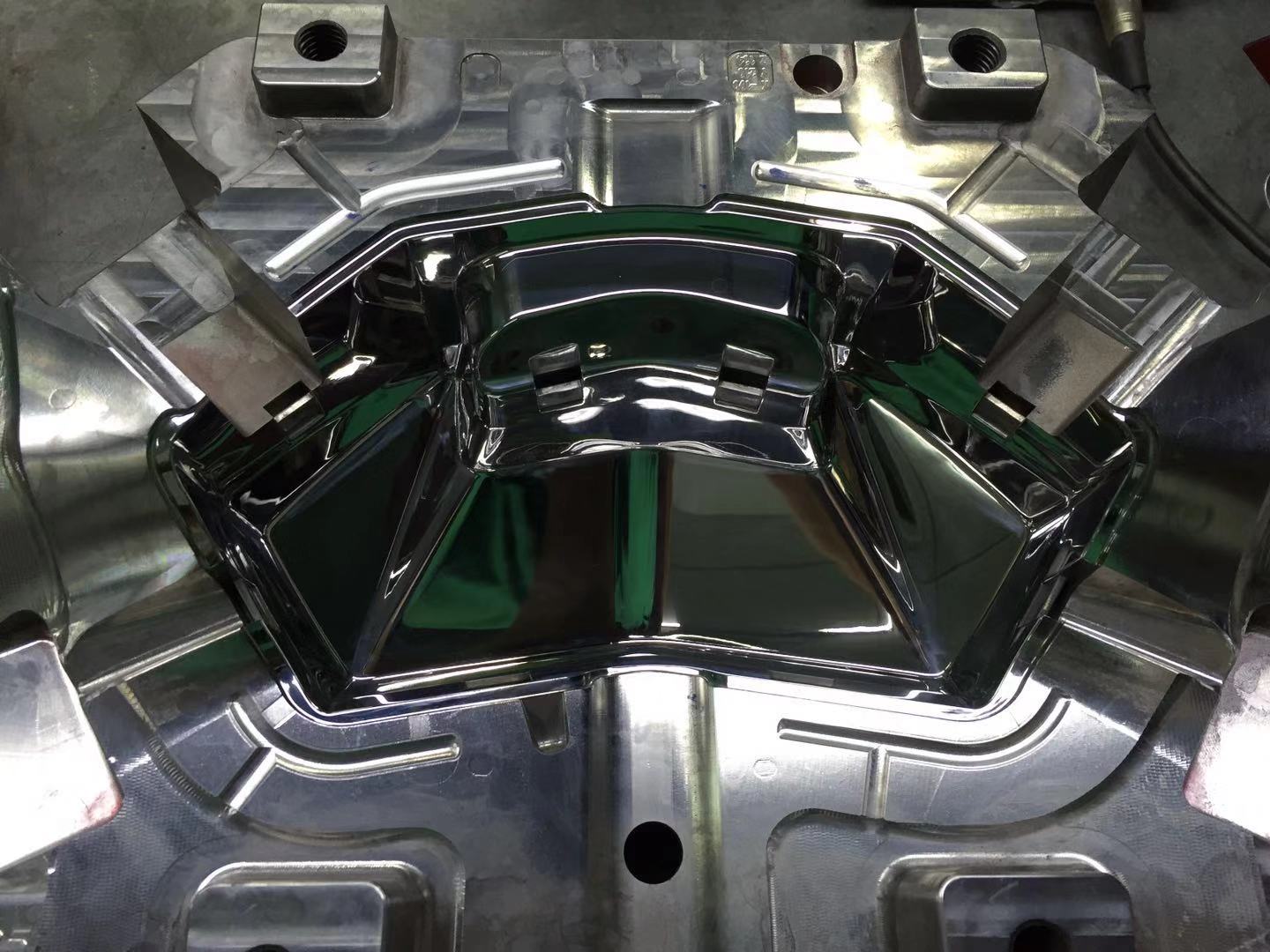

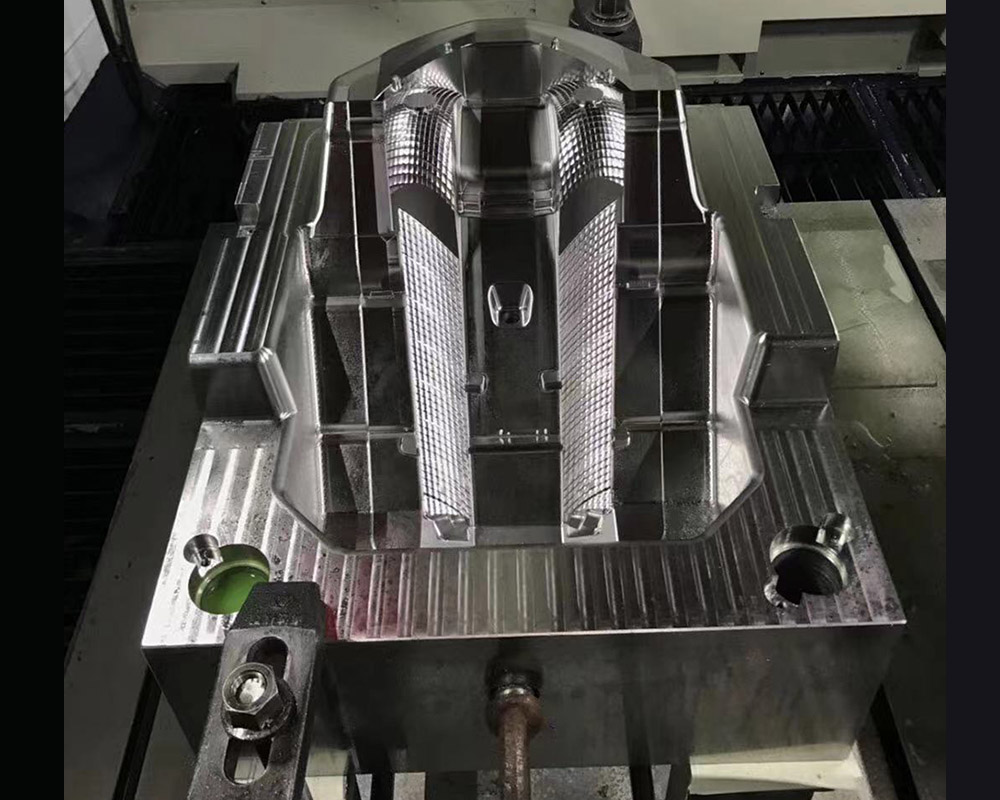

High polishing molds

Mold polishing is a process that involves graded grinding of the mold cavity surface using tools such as oilstones, sandpaper, and polishing paste, aiming to enhance the surface finish and demolding performance of the product. It follows the principle of progressing from coarse to fine, sequentially eliminating machining marks and reducing surface roughness, ultimately achieving a mirror-like finish. The process is divided into three stages: rough polishing, semi-fine polishing, and fine polishing. Rough polishing uses oilstones to remove mechanical marks, semi-fine polishing refines the surface with sandpaper, and fine polishing employs diamond abrasive paste for ultra-precision treatment, achieving a surface roughness standard of up to Ra0.008μm

Mold polishing is a process that involves graded grinding of the mold cavity surface using tools such as oilstones, sandpaper, and polishing paste, aiming to enhance the surface finish and demolding performance of the product. It follows the principle of progressing from coarse to fine, sequentially eliminating machining marks and reducing surface roughness, ultimately achieving a mirror-like finish. The process is divided into three stages: rough polishing, semi-fine polishing, and fine polishing. Rough polishing uses oilstones to remove mechanical marks, semi-fine polishing refines the surface with sandpaper, and fine polishing employs diamond abrasive paste for ultra-precision treatment, achieving a surface roughness standard of up to Ra0.008μm

The technical standards for this process are divided into four levels, from A0 to A4, and are graded and controlled based on surface roughness. The hardness of steel, pretreatment status, and operational techniques directly affect the polishing quality. Among them, ultra-precision lapping and polishing technology is widely used in the processing of optical lens molds. With the increasing demand for appearance quality in plastic products, the level of technical refinement in mold polishing in the injection molding industry continues to improve. Especially in the production of transparent parts and high-gloss surfaces, the level of craftsmanship directly affects the appearance and molding efficiency of the product.