Rapid prototyping

Usually, newly developed or designed products require prototyping, which is the first step in verifying the feasibility of the product. It is the most direct and effective way to identify the defects, deficiencies, and drawbacks of the designed product, so as to make targeted improvements to the defects until the deficiencies cannot be found from individual prototype samples. At this point, it is usually necessary to conduct small-scale trial production to identify deficiencies in the batch and make improvements. The designed products are generally not perfect or even unusable. Once there are defects in direct production, they will be completely scrapped, greatly wasting manpower, material resources, and time; However, the prototype is usually a small number of samples, with a short production cycle and low loss of manpower and material resources. It quickly identifies the shortcomings in product design and improves them, providing sufficient basis for product finalization and mass production.

With the increasingly fierce competition in the social market and the development and growth of the industrial design industry, enterprises not only attach importance to industrial design, but also focus on the production of product models. The development quality and actual effect of the product need to be verified using prototype models. In this situation, the prototype industry gradually separated from the industrial design process and became a relatively independent industry that flourished.

The prototype model industry can be called the sunrise industry of the future, and its development status has its own advantages. Firstly, there is a large social demand, which is directly due to the increase in investment in product research and development by enterprises, and indirectly related to the development of domestic social economy. Secondly, the entry threshold for this industry is relatively low, and it does not require a large amount of capital investment to establish production plants and equipment that meet production requirements. Finally, the added value of this industry is relatively high, and the actual gross profit is much higher than that of typical manufacturing industries, and even higher than that of many design companies.

The prototype model industry can be called the sunrise industry of the future, and its development status has its own advantages. Firstly, there is a large social demand, which is directly due to the increase in investment in product research and development by enterprises, and indirectly related to the development of domestic social economy. Secondly, the entry threshold for this industry is relatively low, and it does not require a large amount of capital investment to establish production plants and equipment that meet production requirements. Finally, the added value of this industry is relatively high, and the actual gross profit is much higher than that of typical manufacturing industries, and even higher than that of many design companies.

The prototype can be divided into handmade prototype and CNC prototype according to production:

(1) Handmade prototype: Its main workload is completed manually. Handmade prototypes are divided into ABS prototypes and clay prototypes

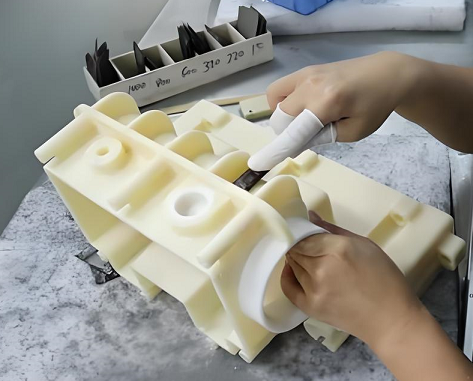

(2) CNC prototype: Its main workload is completed by CNC machine tools, and depending on the equipment used, it can be divided into laser rapid prototyping (SLA) prototype, machining center (CNC) prototype, and RP prototype (3D printing).

(3) RP prototype: It is mainly produced using 3D printing technology. Prototype made by laser rapid prototyping is commonly known as SLA prototype, but laser rapid prototyping is one of the types of 3D printing.

(4) CNC prototype: It is mainly a prototype produced by machining centers.

Compared with CNC prototypes, RP prototypes have their own advantages:

The advantages of RP prototype mainly lie in its speed, but it is mainly formed through stacking technology. Therefore, RP prototype is generally relatively rough and has certain requirements for the wall thickness of the product. For example, if the wall thickness is too thin, it cannot be produced.

The advantages of CNC prototype are reflected in its ability to accurately reflect the information expressed in the drawing, and the surface quality of CNC prototype is high, especially after surface spraying and screen printing, it is even more dazzling than the products produced after mold opening. Therefore, CNC prototype manufacturing is becoming increasingly mainstream in the prototype manufacturing industry.

According to the materials used in production, hand boards can be divided into plastic hand boards and metal hand boards:

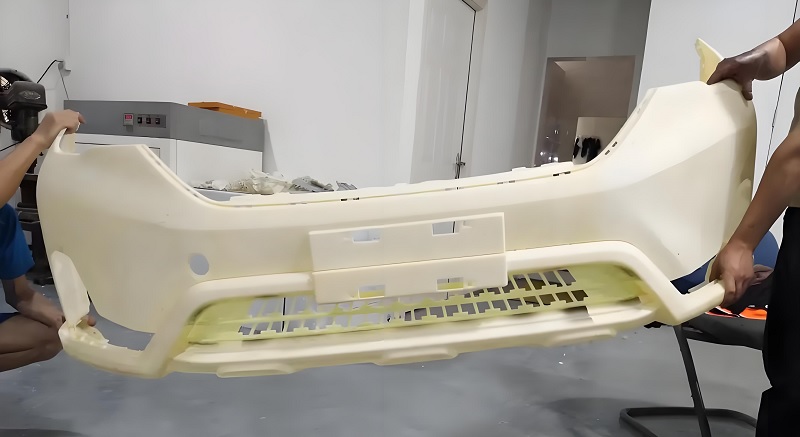

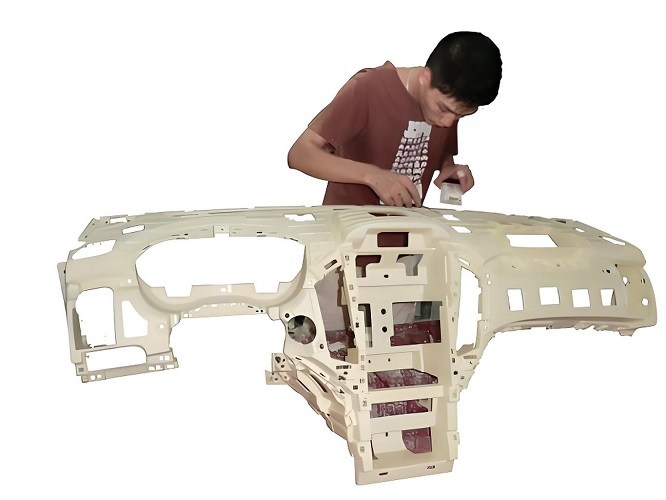

(1) Plastic prototype: Its raw material is plastic, such as cars, mobile phones, toys, handicrafts, daily necessities, televisions, monitors, telephones, and so on.

(2) Metal prototype: Its raw materials are aluminum, iron, copper and other metal materials, mainly used as prototypes for high-end products such as laptops, high-end single players, MP3 players, CD players, etc.

The necessity of making prototypes

Inspect the appearance design:

The prototype is not only visible, but also touchable, which can intuitively reflect the designer's creativity in the form of a physical object, avoiding the disadvantage of "drawing it looks good but making it not". Therefore, prototype production is essential in the process of new product development and product appearance refinement.

Inspect structural design:

Because the prototype is assemblable, it can intuitively reflect the rationality of the structure and the difficulty of installation. Facilitating early detection and resolution of problems.

Direct mold opening risk

Due to the generally high cost of mold manufacturing, larger molds can be worth hundreds of thousands or even millions. If any structural or other problems are found during the mold making process, the losses can be imagined. Prototype production can avoid such losses and reduce the risk of mold opening.

Product launch ahead of schedule:

Due to the advanced nature of prototype production, you can use prototypes to promote your products and even prepare for sales and production before the mold is developed, in order to capture the market early.

Application Fields

Electronic appliances: displays, humidifiers, juicers, vacuum cleaners, air conditioning panels.

Toy anime: cartoon characters, anime merchandise, miniature car models, airplane models.

Medical beauty: medical equipment, beauty tools, nail tools, fitness equipment.

Model aircraft military industry: protective masks, high-precision machined products, etc.

UnionPay security: cash register, ATM, tax control machine, speedometer, 3G camera.

Automobile transportation: car lights, bumpers, seats, electric vehicles.

Architectural display: architectural models, conceptual buildings, exhibition hall layout, display layout.

Craft accessories: PMMA crafts, relief crafts, ornaments, antique utensils.