In the current era of accelerated product development iteration, "quickly obtaining physical data - accurately transforming digital models - achieving innovative design" has become the core of enterprise competitiveness. The deep integration of reverse transcription modeling, product mapping, and industrial design, with a "data-driven+innovation empowered" model, breaks the limitations of traditional design "starting from scratch" and builds a complete closed loop from physical surveying to innovative design, providing a comprehensive solution of "efficient replication, precise optimization, and differentiated innovation" for industries such as manufacturing, consumer electronics, and cultural and creative industries.

Reverse transcription (3D scanning) is a data entry point that utilizes optical technology to achieve global digitization of products. Strong technical adaptability for different product characteristics:

Handheld laser scanners are used for precision parts, such as watch gears and medical equipment accessories, with a single point accuracy of 0.05mm to capture the subtle patterns on the tooth profile surface;

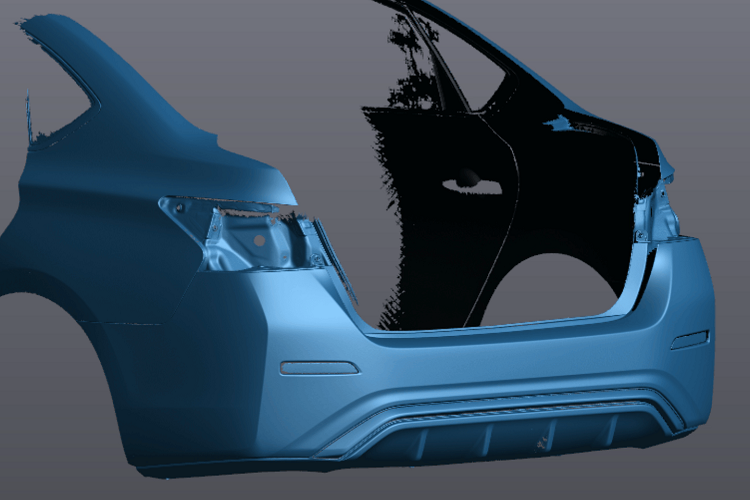

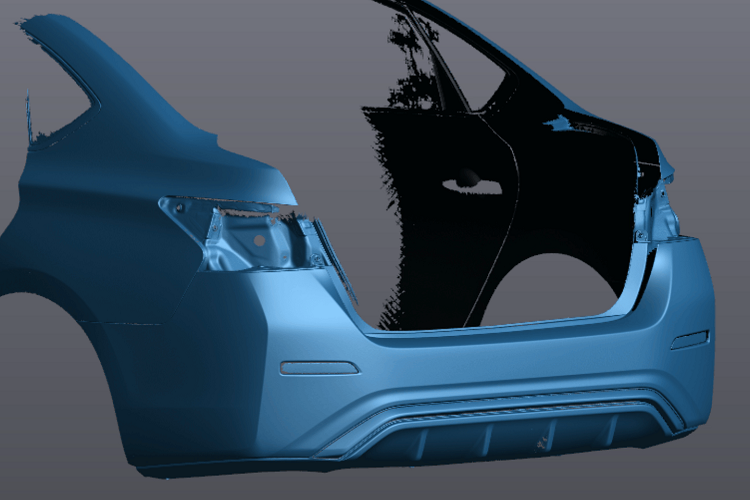

Large products (such as home appliance casings and car bumpers) are scanned using a blue structured light scanner, which can complete a 1-meter range scan within 10 minutes. The point cloud data covers 200 points per square millimeter to ensure the continuity of the curved surface transition;

Fragile or irregular products (such as ceramic cultural and creative products, silicone prototypes) are scanned using non-contact scanning to avoid deformation caused by physical contact, with a data restoration rate of 99%.

This technology breaks through the limitations of traditional surveying and mapping "single point sampling", allowing every detail of the product to be accurately recorded, providing a "digital base map" for subsequent modeling.

(2) Product surveying and modeling: transformation from point cloud to parametric model

A professional team achieves data value conversion through a three-step process:

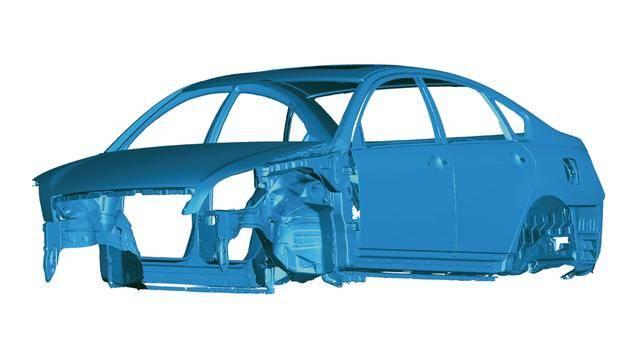

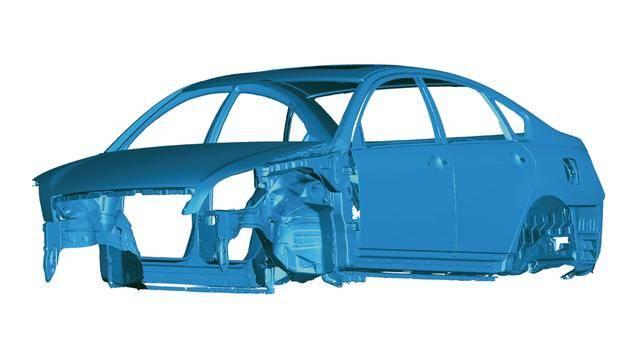

Data purification: Remove scanning noise (such as fingerprints and dust), concatenate multi view data, and ensure that the point cloud alignment error of complex products (such as multi surface combinations) is ≤ 0.03mm;

Feature extraction: Identify the functional features of the product (such as positioning holes, buckles, parting lines), reconstruct the surface using software such as Geomagic, and make the model both "similar in shape" and conform to manufacturing logic (such as reserving mold draft angles);

Parameterized output: Convert the model into editable CAD files, support seamless integration with industrial design software (SolidWorks, Rhino), and lay the foundation for innovative design.

2、 Scene Implementation: Multidimensional Practice of Design Innovation

(1) Manufacturing Industry: Accelerating Product Iteration and Optimization

In the field of automotive components, reverse transcription modeling achieves "benchmarking surpassing": scanning the imported engine cylinder block, mapping its heat dissipation water channel structure, optimizing the curvature of the flow channel during industrial design, improving heat dissipation efficiency by 15% while reducing weight by 8%; In the mold industry, by copying worn molds, modeling and analyzing the deformation law of the mold cavity, and designing compensation schemes, the qualification rate of castings has been increased from 82% to 98%.

(2) Consumer Electronics: Quickly Responding to Market Demand

A certain mobile phone manufacturer received a design requirement for a curved screen concept. By copying existing screen modules and surveying their assembly boundaries, ergonomics were integrated into industrial design to optimize the side curvature from 2.5mm to 3mm. This ensures a comfortable fit for the palm and is compatible with existing production lines. The new product development cycle has been shortened to 45 days, which is 50% less than the traditional process.

(3) Cultural and Creative Design: Integration and Innovation of Tradition and Modernity

Designers scan intangible cultural heritage bamboo weaving crafts, extract parameterized features of weaving textures through surveying, and integrate them into modern lamp housings during industrial design. While retaining traditional patterns, they optimize the structure to adapt to 3D printing mass production, making cultural and creative products both culturally rich and in line with industrial production standards, with annual sales exceeding 100000 pieces.

3、 Core Value: Reshaping the Efficiency and Boundaries of Design and Development

(1) Reduce costs and increase efficiency, shorten the research and development cycle

Reverse copying modeling eliminates the time cost of "drawing from scratch". When a certain home appliance company developed a new type of refrigerator panel, by copying the structure of competing products, the design cycle was reduced from 3 months to 1 month, and the trial and error cost was reduced by 60%; Small batch customized products (such as irregular tools and specialized accessories) do not require mold making and can be directly 3D printed based on surveying models to quickly verify market demand.

(2) Precise adaptation to reduce manufacturing risks

Product surveying ensures seamless integration between design and manufacturing processes: In industrial design, material shrinkage rates (such as 3% for plastic parts and 0.2% for metal parts) are pre-set based on surveying data to avoid dimensional deviations in later production; Annotate key tolerances (such as assembly clearance ± 0.1mm) to directly guide production with design drawings, increasing the first pass rate to 95%.

(3) Empowering innovation and breaking through design limitations

The "data baseline" provided by reverse transcription provides more basis for design innovation: based on surveying data, redundant structures are removed through topology optimization (such as reducing the weight of bicycle frames by 15% while maintaining strength); Integrating the characteristics of new materials (such as replacing steel with carbon fiber) to achieve collaborative innovation of "structure material function".

4、 Future Trends: Intelligent and Ecological Extension

With the integration of AI technology, reverse transcription modeling is achieving "automatic feature recognition" (recognition rate over 90%), and modeling efficiency is improving by 60%; Combining industrial design with digital twins, constructing virtual prototypes based on surveying data, simulating product usage scenarios to optimize details (such as anti slip patterns on handheld devices). This "data+innovation" model is driving design from "experience driven" to "science driven", injecting more precise market adaptability and technological competitiveness into products.

The integration of reverse transcription modeling and industrial design is not only the superposition of technical tools, but also the innovation of design thinking - it makes innovation no longer blind, makes iteration based, and provides a reliable path for enterprises from "precise replication" to "surpassing innovation" in the rapidly changing market.

In the current era of accelerated product development iteration, "quickly obtaining physical data - accurately transforming digital models - achieving innovative design" has become the core of enterprise competitiveness. The deep integration of reverse transcription modeling, product mapping, and industrial design, with a "data-driven+innovation empowered" model, breaks the limitations of traditional design "starting from scratch" and builds a complete closed loop from physical surveying to innovative design, providing a comprehensive solution of "efficient replication, precise optimization, and differentiated innovation" for industries such as manufacturing, consumer electronics, and cultural and creative industries.

In the current era of accelerated product development iteration, "quickly obtaining physical data - accurately transforming digital models - achieving innovative design" has become the core of enterprise competitiveness. The deep integration of reverse transcription modeling, product mapping, and industrial design, with a "data-driven+innovation empowered" model, breaks the limitations of traditional design "starting from scratch" and builds a complete closed loop from physical surveying to innovative design, providing a comprehensive solution of "efficient replication, precise optimization, and differentiated innovation" for industries such as manufacturing, consumer electronics, and cultural and creative industries.