Injection mold flow analysis is a systematic method for optimizing the injection molding process through computer simulation technology, which can reduce trial mold costs by 30% -50% and shorten development cycles by 2-3 weeks.

Technical principles and core modules: Mold flow analysis is based on three-dimensional modeling data and uses finite element algorithm to simulate the flow process of molten metal in the mold cavity. It involves mathematical models such as non Newtonian fluid mechanics and heat conduction equations, and can output key parameter maps such as pressure gradient and temperature distribution. Its core modules include:

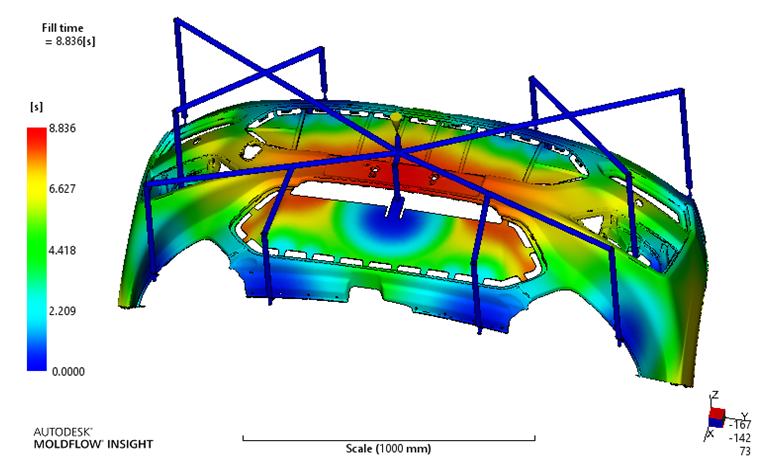

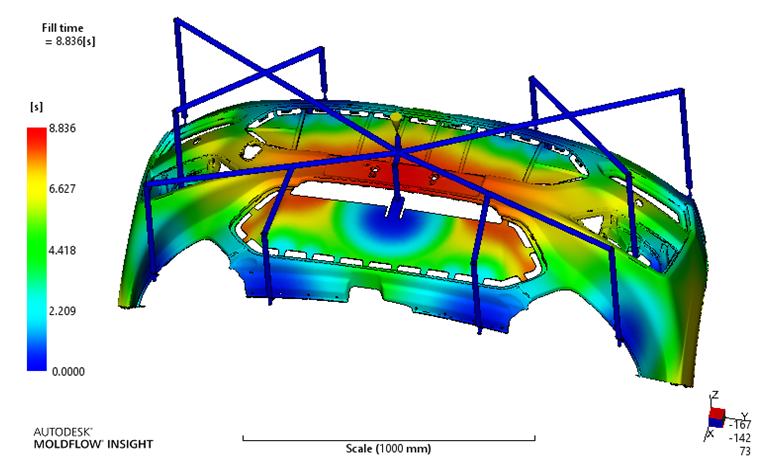

Flow analysis: predict filling time and flow path, optimize gate position, and detect weld lines and air pocket defects;

Cooling analysis: Simulate the heat transfer efficiency of waterways, optimize pipeline distribution to reduce residual stress, and improve the forming efficiency of thin-walled parts by more than 30%;

Warping deformation analysis: predict the three-dimensional deformation of the product based on the material shrinkage rate, and optimize the ejection balance.

Industrial Applications and Software Tools

Application areas: Injection molding of automotive instrument panels (improving mechanical strength), electronic chip packaging (controlling resin flow), medical device molding (reducing defect rates);

Main softwares:

Main softwares:

Moldflow: Supports full process analysis of flow/cooling/warping, with the addition of metal insert simulation function in the 2025 version;

Moldex3D: Provides 3D realistic simulation technology, suitable for complex process analysis;

SIMULIA Simpoe Mold: Integrated multi physics field coupling analysis, commonly used in automotive component development.

Implementation process and key steps:

Data preparation: Import the 3D model of the product, set material properties (such as PVT curve, rheological parameters) and process parameters (injection speed, holding pressure);

Grid division:

Using double-layer or 3D solid grids, the matching rate needs to be above 90%, and the aspect ratio of each element should be controlled within 3:1;

Avoid free boundaries and overlapping intersections to ensure grid quality;

Simulation and optimization: Verify the pouring system and cooling water circuit layout through virtual trial molding, output compensation surface data to correct the mold cavity size.

Injection mold flow analysis is a systematic method for optimizing the injection molding process through computer simulation technology, which can reduce trial mold costs by 30% -50% and shorten development cycles by 2-3 weeks.

Injection mold flow analysis is a systematic method for optimizing the injection molding process through computer simulation technology, which can reduce trial mold costs by 30% -50% and shorten development cycles by 2-3 weeks.  Main softwares:

Main softwares: